The figure below is a schematic of the position control system.

As a simplification we have omitted the gearbox and absorbed its

effect into the values of ![]() and

and ![]() .

We have also absorbed the reflected moment of intrtia of the gears

and motor armature into

.

We have also absorbed the reflected moment of intrtia of the gears

and motor armature into ![]() .

.

![\includegraphics[scale=1.000000]{scan8.1.ps}](img241.png)

This translates into the following block diagram

![\includegraphics[scale=0.500000]{ckt8.7.ps}](img242.png)

.

Integrating the angular velocity

.

Integrating the angular velocity ![\includegraphics[scale=0.650000]{ckt8.6.ps}](img243.png)

Previously we have used another motor as a tachogenerator to

measure speed.

We will be using a type of variable resistor known as a

potentiometer

to measure the angle of the gearbox output.

A

potentiometer

(or

pot

for short)

is a fixed value resistor with a third, movable contact

or

slider

which may be positioned anywhere along the

resistive element.

If we represent the position of the slider by

![]() , where

, where ![]() varies between 0 (fully counterclockwise)

and 1 (fully clockwise), then the resistance between the lower

end of the resistor and the slider will be

varies between 0 (fully counterclockwise)

and 1 (fully clockwise), then the resistance between the lower

end of the resistor and the slider will be ![]() and between

the slider and the upper end will be

and between

the slider and the upper end will be ![]() ,

where

,

where ![]() is the total resistance of the potentiometer.

is the total resistance of the potentiometer.

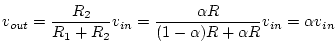

If we connect the two fixed contacts to a voltage source and measure the output between the movable contact and one fixed contact, we get a variable voltage divider:

![\includegraphics[scale=0.650000]{pot1.ps}](img244.png)

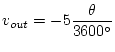

Then the output is

The potentiometer we are using is a

10-turn

pot, which means that ten turns

(![]() )

of the shaft are required to go from

)

of the shaft are required to go from

![]() to

to ![]() .

We will be using -5 V for

.

We will be using -5 V for ![]() , so

, so