![\includegraphics[scale=0.650000]{motor1.ps}](img195.png)

An ideal DC motor looks like this schematically:

![\includegraphics[scale=0.650000]{motor1.ps}](img195.png)

Some texts (including Cogdell) state these equations as

![]() and

and

![]() ,

to indicate the dependence

of the torque and back emf

on the strength of the magnetic flux (

,

to indicate the dependence

of the torque and back emf

on the strength of the magnetic flux (![]() ) in the motor.

In some types of DC motors

(so called

wound field

motors)

this flux may be changed by varying a second current,

called the

field current

(

) in the motor.

In some types of DC motors

(so called

wound field

motors)

this flux may be changed by varying a second current,

called the

field current

(![]() ).

In a permanent magnet motor,

).

In a permanent magnet motor, ![]() is fixed

by the strength of the permanent magnets,

so we will absorb the

is fixed

by the strength of the permanent magnets,

so we will absorb the ![]() into the constants

into the constants ![]() (and use lower case subscripts)

to simplify the equations.

(and use lower case subscripts)

to simplify the equations.

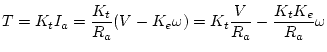

Just like a real battery departs from ideal because of its

internal resistance,

a real motor also contains a resistance,

called the

armature resistance

(![]() ) in series with an ideal motor.

This gives the following circuit:

) in series with an ideal motor.

This gives the following circuit:

![\includegraphics[scale=0.650000]{motor2.ps}](img196.png)

Now, although the armature current ![]() is still equal to the

current

is still equal to the

current ![]() flowing into the motor,

the voltage

flowing into the motor,

the voltage ![]() across the motor terminals is no longer equal to

the back emf

across the motor terminals is no longer equal to

the back emf ![]() .

Instead we have, using KVL:

.

Instead we have, using KVL: ![]() .

Combining this with the coupling equations for the ideal motor,

we get:

.

Combining this with the coupling equations for the ideal motor,

we get:

If we apply a voltage source to a motor with no mechanical load

connected to it, then the torque produced by the current,

![]() ,

will act to accelerate the rotor of the motor.

However, as the velocity

,

will act to accelerate the rotor of the motor.

However, as the velocity ![]() increases,

it produces a back emf

increases,

it produces a back emf ![]() which opposes the applied voltage.

Thus, rather than continuing to accelerate indefinately, the

motor reaches an equilibrium

when

which opposes the applied voltage.

Thus, rather than continuing to accelerate indefinately, the

motor reaches an equilibrium

when

![]() where

where ![]() is called the

no load speed.

is called the

no load speed.

On the other hand, if we lock the rotor so that it can't turn

(i.e.

stall

the motor)

the current

![]() will continue to flow, producing

the

stall torque

will continue to flow, producing

the

stall torque

![]() .

Stated another way, if a load greater than

.

Stated another way, if a load greater than ![]() is required,

the motor will stop, or stall.

is required,

the motor will stop, or stall.

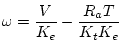

For values of load torque between zero and ![]() , we have

the relations

given above.

If we plot

, we have

the relations

given above.

If we plot ![]() vs.

vs. ![]() for a fixed voltage

for a fixed voltage ![]() ,

we get what is called a

constant voltage speed-torque curve.

If we change the voltage, the curve will move up or down,

giving a set of speed vs torque relations, one for each

voltage.

,

we get what is called a

constant voltage speed-torque curve.

If we change the voltage, the curve will move up or down,

giving a set of speed vs torque relations, one for each

voltage.

![\includegraphics[scale=0.650000]{speedtorque.ps}](img197.png)

In reality, the load torque is never zero. There will be some friction in the bearings, aerodynamic drag on the rotor, etc. Also, some types of motors have preferred orientations or detents where the magnets try to hold the rotor at a particular angle. This gives rise to a ripple torque which varies depending on the angle of the shaft. This will cause us some difficulty when we try to measure the torque characteristics of our motor, and can cause no end of grief when trying to use a motor with this characteristic in certain applications (fortunately not in ours).