Let's apply our new Labview skills to

the task of improving

the resistance/temperature

measurement system we built last week.

| |

|

|

Step 1: |

|

Restore the connections you had in

Experiment 3.2 last week

with

the 0-6 V output of the power supply (set to 5.00 V)

connected to J1-3.

Check that the circuit on your breadboard is still wired correctly.

Load and run the VI you saved last week and verify that it still

produces the correct reading for temperature.

Vary the power supply voltage and observe that the temperature

reading changes in response.

|

Step 2: |

|

Stop the VI.

On your breadboard, add a wire to connect  to

ach4,

so that your circuit looks like this:

to

ach4,

so that your circuit looks like this:

![\includegraphics[scale=0.500000]{ckt3.3.5.ps}](img229.png)

|

Step 3: |

|

We are now asking the A/D converter to read two different

voltages simultaneously. This is not a problem for the A/D

converter, but it does require

us

to figure out how Labview represents multiple simultaneous samples.

The obvious way to handle this would be to simply add another A/D

block and set it to A/D Channel 4.

If you try this, you will get a cryptic error message to the

effect that the device is already in use. This is because all of

the channels are on the same card, and the first channel which is

opened has exclusive use of the device.

Labview handles this by combing multiple samples into a

vector,

with one entry for each channel.

Double click the A/D block or select

Properties

from the menu.

This will bring up the

DAQ Assistant

dialog.

Click on the

Show Details

button near the top of the panel

|

Step 4: |

|

Click on the

Add Channels

button.

Select

Voltage

from the popup menu,

then select

ai4

from the list of Supported Physical Channels.

A new entry for ai4 should appear in the channels list.

Note the

Scan Order

column.

This tells us that channel 5 will be the first element of the

vector of samples and channel 4 will be the second.

Although this seems untidy, it won't cause problems

as long as we remember the order.

Click

OK

and wait until everything has settled down.

Select

Voltage

from the popup menu,

then select

ai4

from the list of Supported Physical Channels.

A new entry for ai4 should appear in the channels list.

Note the

Scan Order

column.

This tells us that channel 5 will be the first element of the

vector of samples and channel 4 will be the second.

Although this seems untidy, it won't cause problems

as long as we remember the order.

Click

OK

and wait until everything has settled down.

|

Step 5: |

|

The block diagram looks the same as before, but now the wire

is carrying two separate values.

Perhaps surprisingly, this fact does not change the original

operation of the VI.

Subsequent blocks, expecting a single value, simply take the first

element of the vector.

Since we left the original signal

( ) as the first element, everything to the right of the

A/D converter block works as it did before.

Start the VI and verify that this is the case.

) as the first element, everything to the right of the

A/D converter block works as it did before.

Start the VI and verify that this is the case.

|

Step 6: |

|

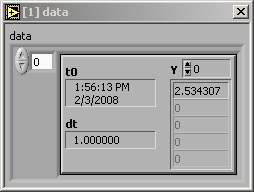

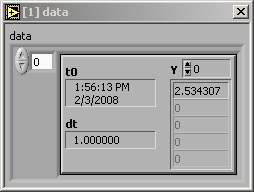

If we know how to look, we can see that the wire coming out

of the A/D converter block is in fact carying two values.

With the VI still runing, bring the block diagram window to

the top.

Place the cursor over the wire between the

DAQ Assistant

block and the numeric indicator labeled

VT.

The wire should start flashing and the cursor will turn into

a circle with the letter "P" in it.

This is the symbol for a

probe.

Left click to place the probe.

A small rectangle labeled

1

will appear at the output of the A/D converter block

and a window labeled

[1] data

will pop up.

and a window labeled

[1] data

will pop up.

The probe display window

shows the value of the data on the probed wire.

The numeric control in the upper left corner

(currently zero) determines

which of the wire's signals is displayed.

Type "1" into this field or click on the upper arrow to

the left of the box.

The value displayed for

Y

should change to a value close to 5.

The probe display window

shows the value of the data on the probed wire.

The numeric control in the upper left corner

(currently zero) determines

which of the wire's signals is displayed.

Type "1" into this field or click on the upper arrow to

the left of the box.

The value displayed for

Y

should change to a value close to 5.

|

Step 7: |

|

Stop the VI.

Widen the block diagram window, or scroll it to create some

empty space to the left of the while loop.

Place the cursor on the border of the while loop.

Resize handles (small black squares) should appear.

Place the cursor over the one in the center of the left edge

and widen the while loop by about an inch.

move the

DAQ Assistant

near the left edge of the loop.

|

Step 8: |

|

Click on the wire segment coming out of the

data

terminal of the

DAQ Assistant

block

and press

Delete

to remove it.

The remainder of the wire will become broken,

since there is now no input.

From the

Functions

palette, select

Sig Manip,

then

Split Signals.

Place the resulting icon between the

A/D converter output and the leftmost

portion of the broken wire, and click to release.

The split signals block is expandable to accomodate the

number of signals in a bundle.

Place the cursor over the middle of the bottom edge and

move it around until it turns into a resize arrow.

Drag the bottom edge down by one increment.

The resulting icon will look like a wishbone in a box.

|

Step 9: |

|

Wire the left side

of the split signals block

to the A/D output.

The upper output is  (ach5).

Connect it to the broken

(ach5).

Connect it to the broken  wire.

wire.

|

Step 10: |

|

The lower output is  , which will replace

the constant value of 5 currently connected to

the upper input of the subtract block.

Delete this numeric constant block and wire the

lower output of the split signal block

to its previous destination.

, which will replace

the constant value of 5 currently connected to

the upper input of the subtract block.

Delete this numeric constant block and wire the

lower output of the split signal block

to its previous destination.

|

Step 11: |

|

Start the VI and verify that the displayed temperature value is still correct.

Vary the value of  and verify that it remains correct.

and verify that it remains correct.

|

Much of what we will do in subsequent Labs,

especially Labs 7 and 8,

will be devoted to minimizing the effect of noise.

For now we will content ourselves with the most common

response to unwanted variation in data:

taking the average.

| |

|

|

Step 1: |

|

Before we start to improve the situation, let's try to get

a quantitative idea of how bad it is.

At the moment what we know is that the displayed value

jumps around a lot. Let's get a picture of those jumps.

Stop the VI and go to the front panel.

Right click to bring up the

Controls

palette, go to

Graph Inds,

and select

Chart

from the

Graph Indicators

palette.

Place the resulting chart in a convenient location on the

front panel.

|

Step 2: |

|

Use

Find Terminal

or your own navigational skills to find the

icon for the

Waveform Chart

on the block diagram.

Position it directly above the icon for the

VT

numeric indicator.

Connect its input to the

T

output of the formula node.

|

Step 3: |

|

Return to the front panel and start the VI.

The chart will provide a graphic record of the variations

in the temperature reading.

Accumulate about a minute's worth of readings,

then stop the VI and make a printout of the front panel.

|

Step 4: |

|

Go to the block diagram and widen the left-hand of the while

loop by about 1.5 inch.

Move the

DAQ Assistant

block to the left edge of the while loop.

Disconnect the

data

output of the

DAQ Assistant

block from the input of the

split signals block.

|

Step 5: |

|

Right click to bring up the

Functions

palette, select

Analysis,

then

Statistics.

Place the resulting block between the

DAQ Assistant

block and the split signals

block.

When the

Configure Statistics

dialog appears, select

Arithmetic mean,

then click

OK.

Connect the output of the

DAQ Assistant

block to the

Signals

input of the

Statistics

block.

Connect the

Arithmetic Mean

output to the input of the split signals block.

|

Step 6: |

|

If we were to run the VI at this point, we would get

the same behavior as before.

This shouldn't be surprising, since the average of

a single value (the

1 Sample

from the

A/D converter)

is just the

original value.

What we need to do is take the average of a large number of

input values to produce a single output.

Double click on the

DAQ Assistant

block to bring up the configuration dialog.

Under

Acquisition Mode,

change

1 Sample (On Demand)

to

N Samples.

Under

Clock Settings,

set

Samples To Read

to 1000.

Since the

Rate

is 1000 samples per second, this will give us 1000

values to average.

Click

OK.

|

Step 7: |

|

Since the process of gathering the 1000 samples now consumes

one second, the

Time Delay

block is no longer needed.

Either delete it, or edit it and set the delay to zero.

|

Step 8: |

|

Return to the front panel and start the VI.

The signal on the

Waveform Chart

should be much smoother.

In fact we might be willing to believe that the variations

that remain correspond to actual changes in temperature.

Save a minute of new data and print a copy to compare

with the unsmoothed plot.

|

Step 9: |

|

Stop the VI and save it in a persistent location.

|

| |

|

|

Step 1: |

|

In the circuit from the previous Part,

replace the thermistor with your CdS photocell.

|

Step 2: |

|

Make a copy of the

VI you used in the previous part and give it an appropriate name.

Load this VI and go to the block diagram.

|

Step 3: |

|

Based on the information in the CdS photocell data sheet,

derive a formula which gives the illumination level (in Lux)

in terms of the resistance.

|

Question 1: |

|

Summarize your derivation in a form that will convince both

you and your labbie of its correctness.

|

Step 4: |

|

Replace the formula in the formula node of the block

diagram with the one you derived in the previous step.

On the front panel, change the label of the temperature

display from

T

to

Illumination.

|

Step 5: |

|

Since light can vary much more rapidly than temperature,

the

Waveform Chart

display would be more useful with a faster update rate.

Edit the A/D converter block and change the

Samples To Read

from 1000 to 100.

|

Step 6: |

|

Start the VI and verify that it works correctly.

|

Step 7: |

|

Determine the illumination level under various conditions:

under-shelf flourescent lamp on or off, incandescent lamp

on or off, photocell shaded by lab notebook, etc.

If necessary,

clear the plot by right-clicking over the display window

and selecting

"Clear Chart".

|

Step 8: |

|

Turn off the incandescent lamp and under-shelf flourescent lamp.

Clear the plot.

Observe changes in the illumination seen by the photocell

as people move around in the vicintity of the lab station.

|

Question 2: |

|

Suggest how the information in the illumination vs. time

plot could be used in an intrusion detector.

|

Step 9: |

|

Set the (old-fashioned, analog) function generator

to produce a 1 Hz, 8 V p-p square wave.

Use BNC clip leads to connect a red LED to the

50 Ω

Output

(polarity is not important).

The LED should be flashing at a rate of once per second.

|

Step 10: |

|

Hold the LED over the photocell, pointing downward.

Observe the resulting waveform on the

Waveform Chart

display.

Increase the distance between the LED and the photocell

and note the maximum distance at which the signal from

the LED is still discernable in the displayed waveform.

|

Remark: |

|

The last step provides an example of an optical

communication system where the signal delivered

to the LED is transfered over an optical channel

to emerge (somewhat the worse for wear) some distance

away as the output of the photocell.

This is essentially the same arrangement we used

in Part 3 of Experiment 2.3, except we're using

the photocell instead of the photodiode.

The response of the photodiode is much faster

than that of the photocell,

but we found that its output voltage was a distorted

version of the optical input.

The I-V plot we made for the photodiode in Experiment

4.3 suggests the reason for this:

viewed as a

current

source the photodiode's output is linear in

the input irradiance, while viewed as a

voltage

source its output is logarithmic.

We will deal with this next week by building

a cicruit which converts this output current to a voltage.

|

![\includegraphics[scale=0.500000]{ckt3.3.5.ps}](img229.png)

![\includegraphics[scale=0.500000]{ckt4.2.2.ps}](img230.png)