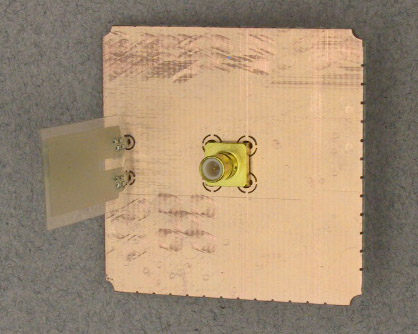

Measure response to bending.

(Click to enlarge)

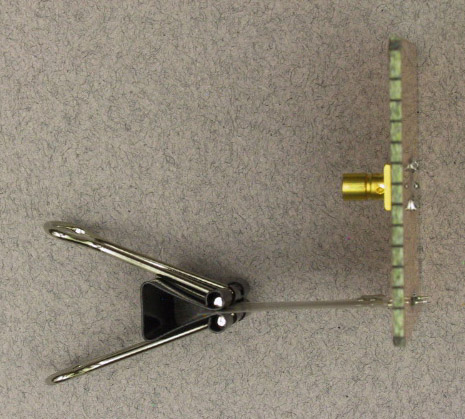

Measure response to vibration.

(Click to enlarge)

Use as a microphone.

Use as a speaker.

This week in the lab we will play with two types of sensors, resistive and piezoelectric. Resistive sensors were discussed in the Background section and a resistive sensor is the subject of this week's design challenge. In the structured part of the lab we will look at two piezoelectric transducers: a vibration sensor and an ultrasonic transceiver.

A piezoelectric material is one in which the electric polarization changes in response to mechanical strain. Commonly used materials include crystals (e.g. quartz), ceramics (e.g. barium titanate), and polymers (e.g. polyvinylidene fluoride (PVDF)). A typical transducer consists of a thin piece of piezoelectric material with a conductive electrode on each surface. When deformed, the change in polarization is manifest as a variation in surface charge, which results in an electric field within the material, which appears as a voltage at the electrodes. In other words, the device looks like a capacitor whose charge is a function of mechanical strain.

This effect works in reverse: applying a voltage to the electrodes establishes an electric field in the material, which in turn produces a mechanical stress. This stress will interact with the elastic properties of the material to produce a corresponding strain or mechanical motion.

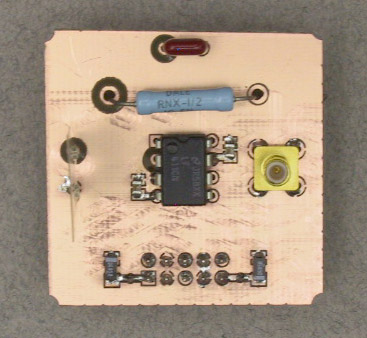

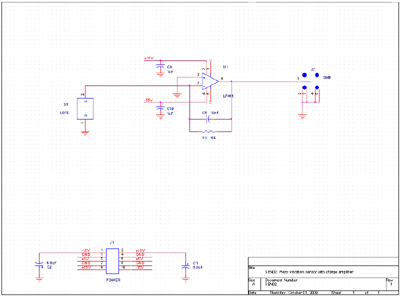

The LDT Vibration Sensor consists of a piece of piezoelectric film which produces a voltage when bent, or which will bend when a voltage is applied.

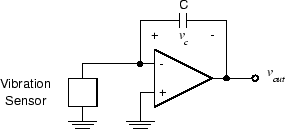

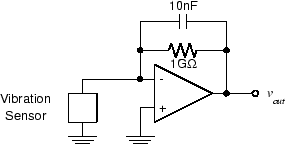

One problem with trying to measure the voltage produced by a piezoelectric sensor is that the finite input impedance of the measurement device (the oscilloscope in our case) rapidly drains the charge from the capacitor and the output decays to zero. For AC signals above the cutoff frequency of the resulting high pass filter, this isn't a problem, but if we want to measure low frequency or static displacements, we need a very high or infinite input impedance. Infinite impedances are hard to come by, but we can get a very large one by using a FET input op amp, such as the LF411.

We could configure the LF411 as a voltage follower and use it as a buffer, but high impedances are susceptable to noise pickup. A better approach is to remove the charge from the sensor (via a very low impedance connection) and place it on another capacitor. If we connect the vibration sensor as shown in Fig. 1 the charge will flow into the summing junction of the op-amp and be transfered to the capacitor. Because of the extremely high input resistance of the LF411 op-amp, it will take a much longer time for this charge to leak away.

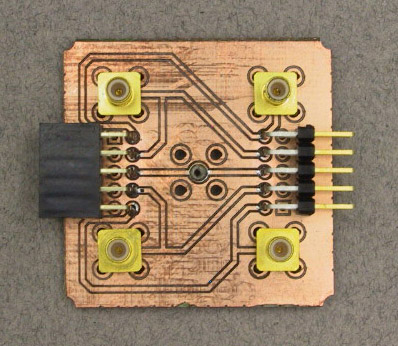

Up to now all of our modules have used surface mount components. 1 GΩ resistors aren't available in surface mount packages, and we had some LF411s available in DIP packages, so this module provides an example of how to use thru-hole components with our milled PC boards. Note that several of the leads are soldered on both sides of the board to provide a via function.

| ||

Vibration: |

Repeat the vibration and microphone measurements from the previous section.

Compare the results with and without the charge amplifier.

| |

Low |

Move the tip of the vibration sensor back and forth

while observing

vout.

You should see a voltage which is proportional to

the deflection.

| |

Displacement: |

Release the sensor and allow

vout

to stabilize.

Move the tip of the sensor a few millimeters and hold

it in position. How long does it take for the

output to decay back to zero.

What happens when you release the sensor?

Allow

vout

to stabilize again,

then move the tip exactly 10 mm.

Measure the resulting output voltage.

| |

Acceleration: |

Attach the binder clip as in the previous section. Allow the output to stabilize, then tilt the breadboard assembly and observe the output. |

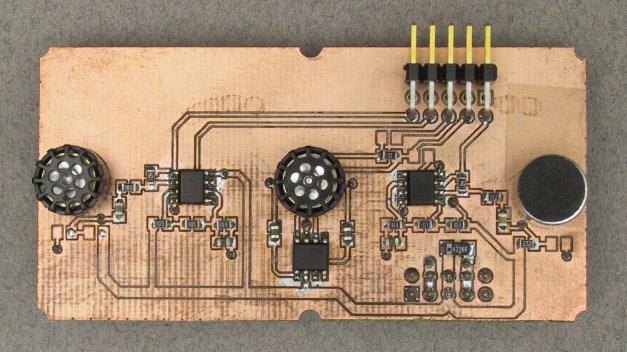

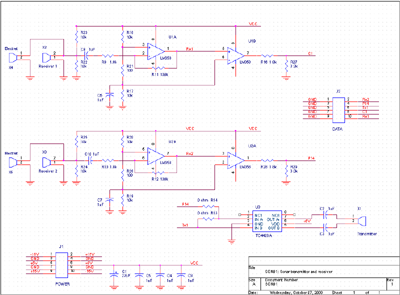

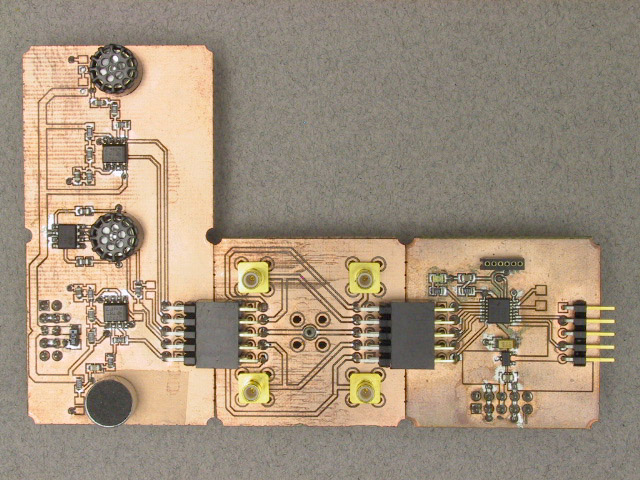

Our third module for this week utilizes such transducers to generate and receive the pulses, some circuitry to drive the transmitter and amplify the received signal, and the MSP430 to generate the pulse.

As with the motor driver of Exercise 4, this circuit has several options which may be selected by jumpers or choice of installed components. It is currently wired with a piezoelectric receiver on the left hand side and an electret microphone on the right. This allows us to compare the sensitivity of the resonant receiver with that of a broadband transducer.

| ||

Connect the modules. |

We have a new connector module which allows us to monitor the signals between the MSP430 and the sonar transciever.

(Click to enlarge) When it's all put together, it looks like this:

(Click to enlarge)  | |

Connect the scope. |

Using the SMB connectors on the intermediate module,

connect channel 1 of the scope to the transmitter drive signal on P1.4

(the connector in the lower left corner).

Connect channel 2 to the receiver output signal Rx1

(upper right corner).

Set the scope to trigger on channel 1.

| |

Build, load, and run the program. |

Compile, load, and run the program lab6.c from this week's

zip file.

The green LED on the CPU board should come on.

| |

Look at the signals. |

Set the time time base to about 50 µs per division.

You should see 8 cycles of a 40 kHz square wave on the transmitter drive.

Set the time base to about 2 ms per division.

You should see a large burst on the receiver output immediately after the

transmitter burst.

Set channel 2 to AC coupling and increase the gain until you can see the

echo of the ceiling at about 12 ms.

Use dual sweep with delayed trigger to get a closer look at the echo.

Place various objects in the path of the beam, move them up and down, and observe the resulting echoes. Move channel 2 to the comparator output (upper left connector) set the gain back to 2 V/div, and the coupling back to DC. Is the ceiling echo detected? Place and move other objects above the beam and assess how effective the comparator output is in determining their distance. |